Evolve Golf

Director of Product Design, Wilmington, NC, 2016–17

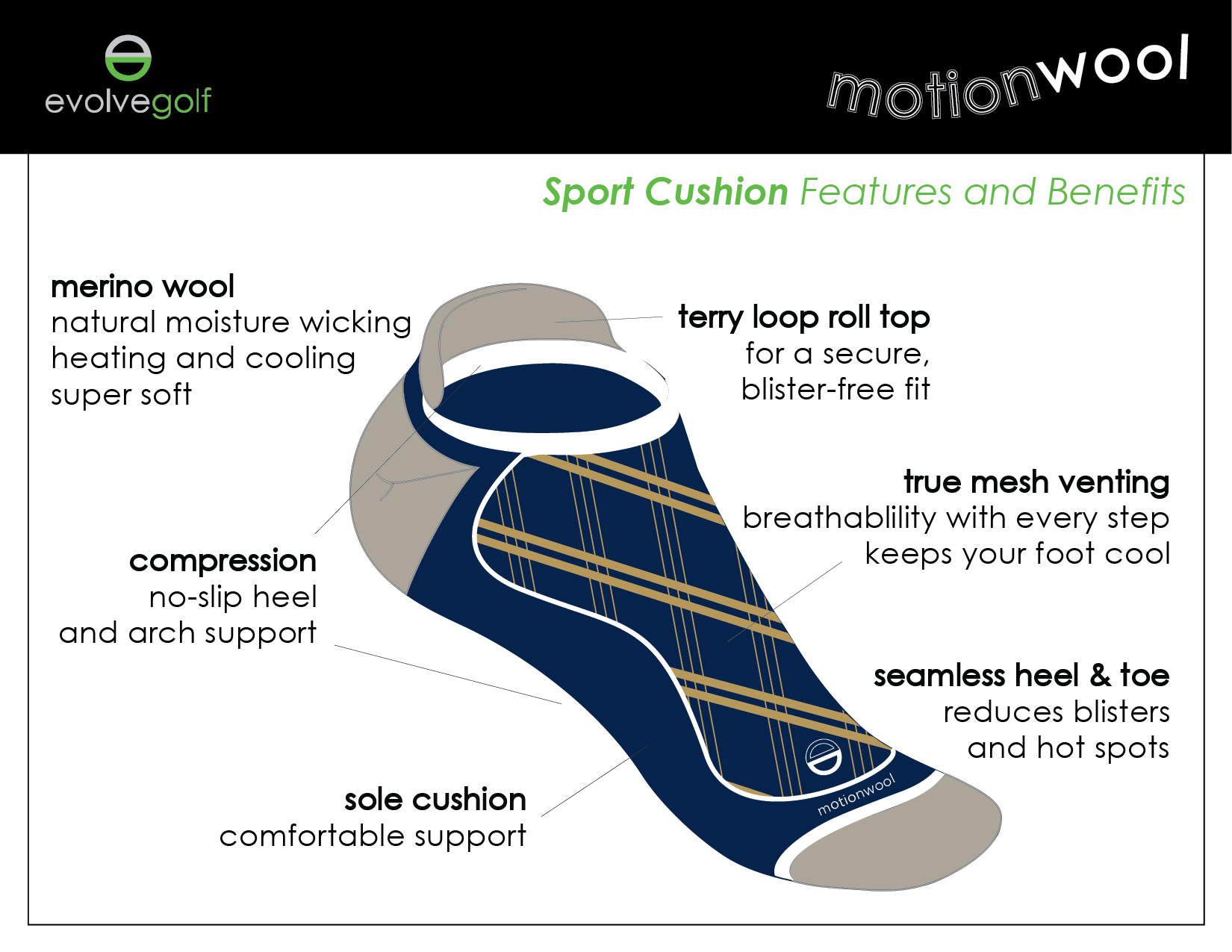

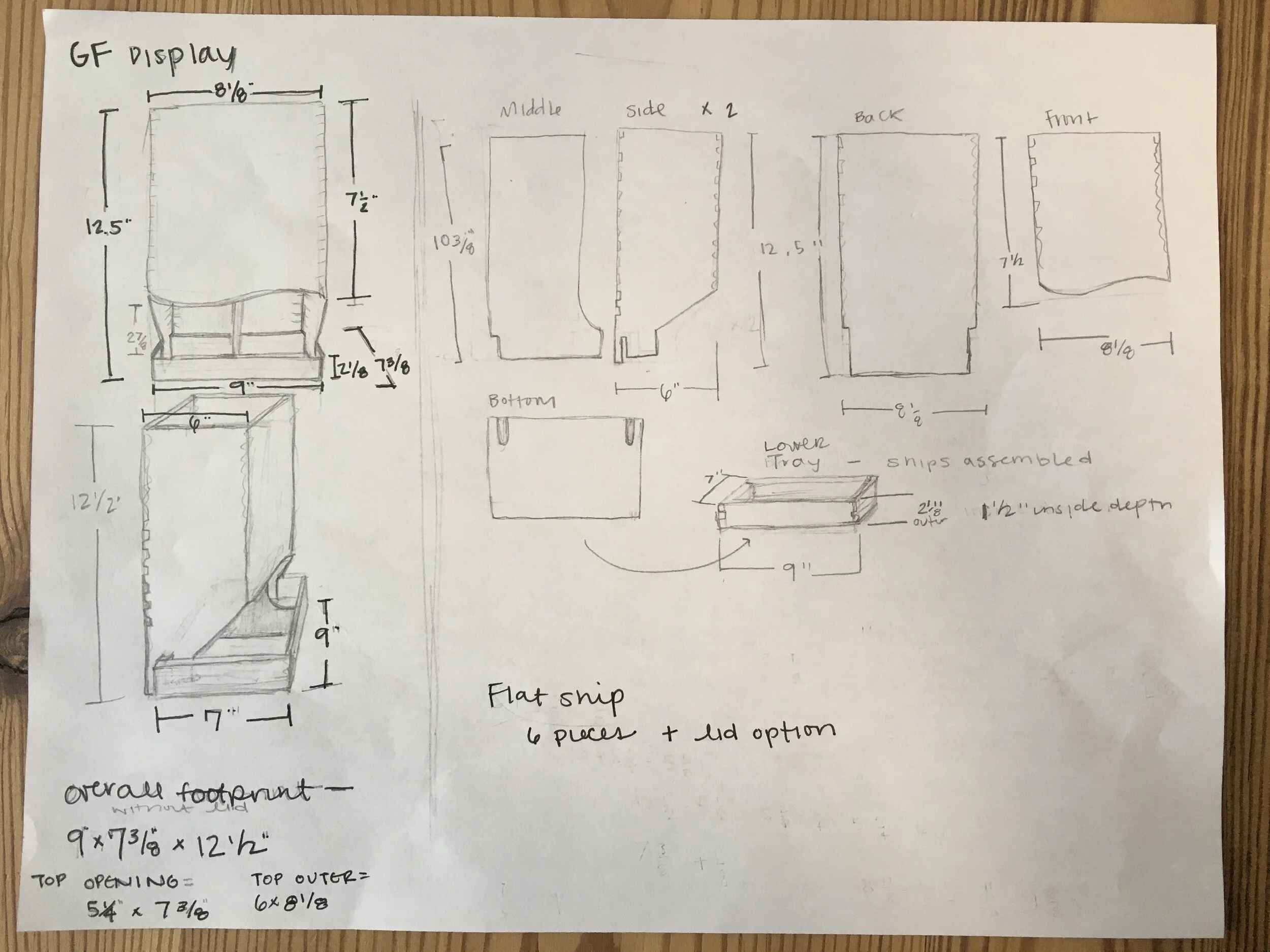

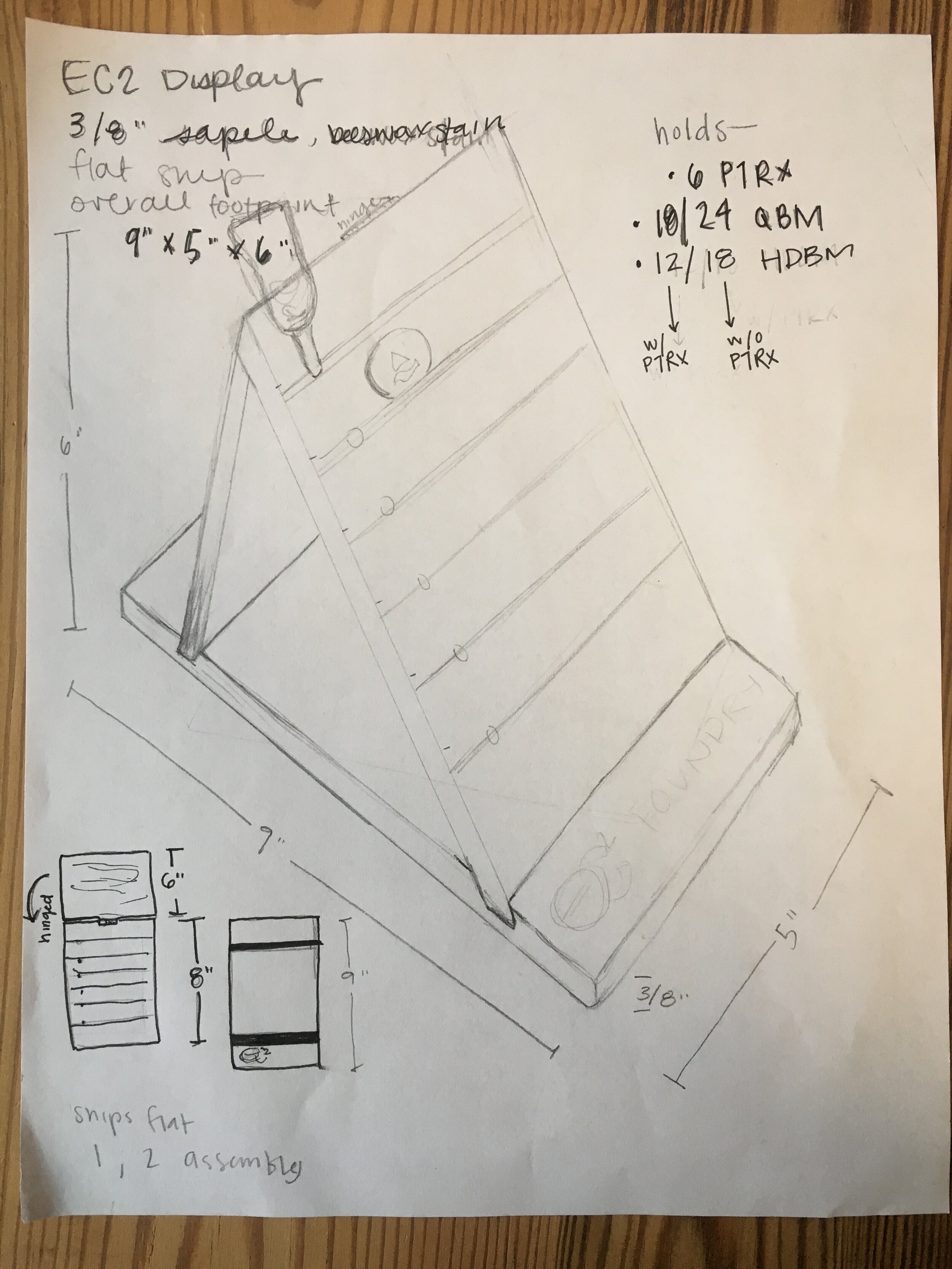

In my tenure at Evolve Golf, I singularly launched, branded, and operated Evolve Golf's production design studio, EC2, housing direct-to-surface and 3-D printers, a wood shop, and metal casting studio. I worked directly with the CEO in the development and creation of new product lines including Motionwool socks + headcovers, PRx metal pitch repair tools and ball markers, Little Black Box monthly subscription golf essentials box, and the Weekend Trail Box.

roles: graphic design, packaging design, 3D design, fabrication, project manager, product photography

tools + machines: SawStop table saw, drill press, miter saw, hand + CNC routers (ShopBot), LogoJet UV Printer, LulzBot TAZ Pro 3D Printer, 2 Ton Hydraulic Press, bench grinder

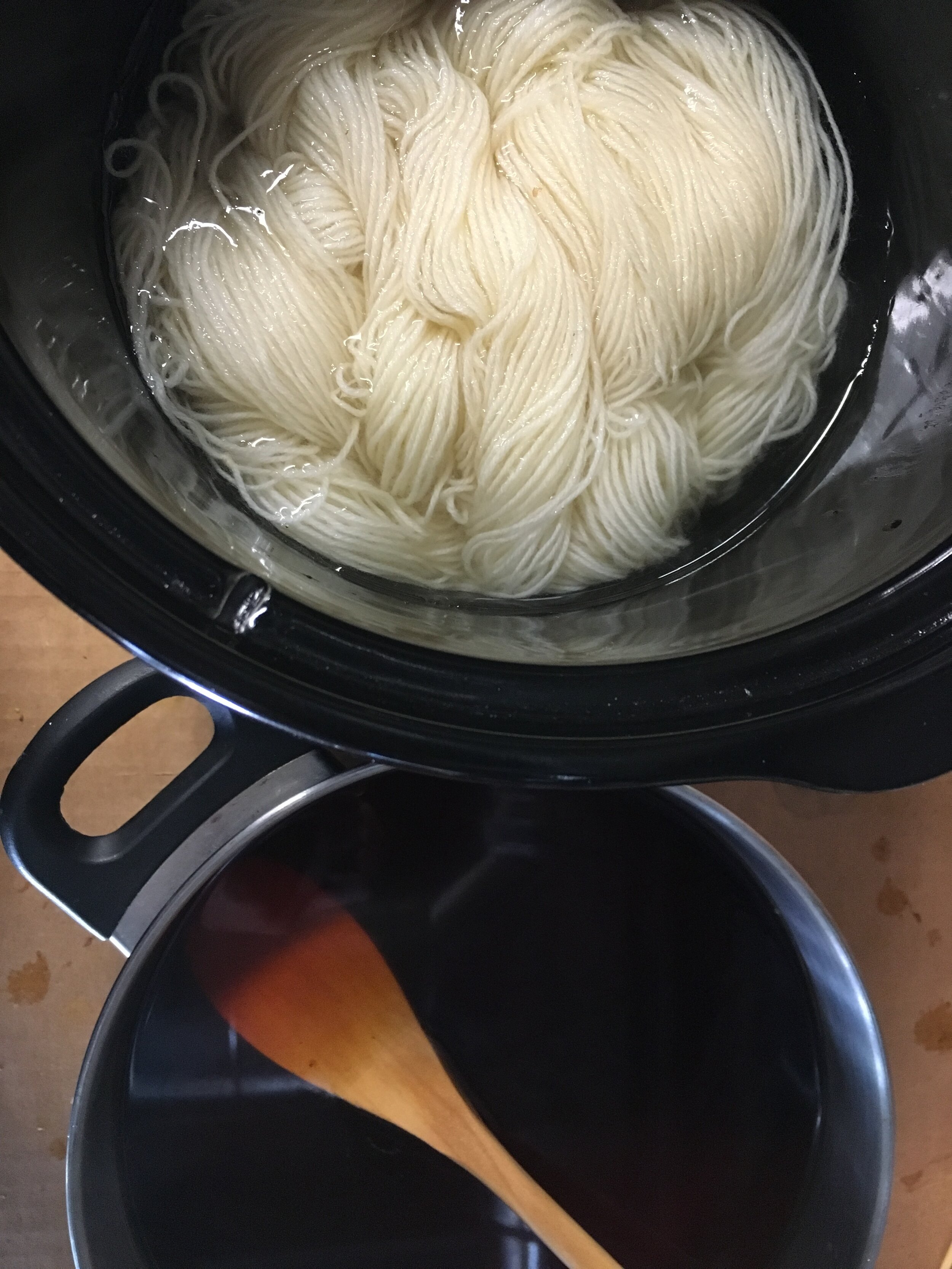

processes: lost wax casting, sandcasting, natural dyeing, metal stamping + patinas, mold-making, laser cutting, woodworking

programs: Adobe Photoshop, Adobe Illustrator, Rhinoceros 3D CAD

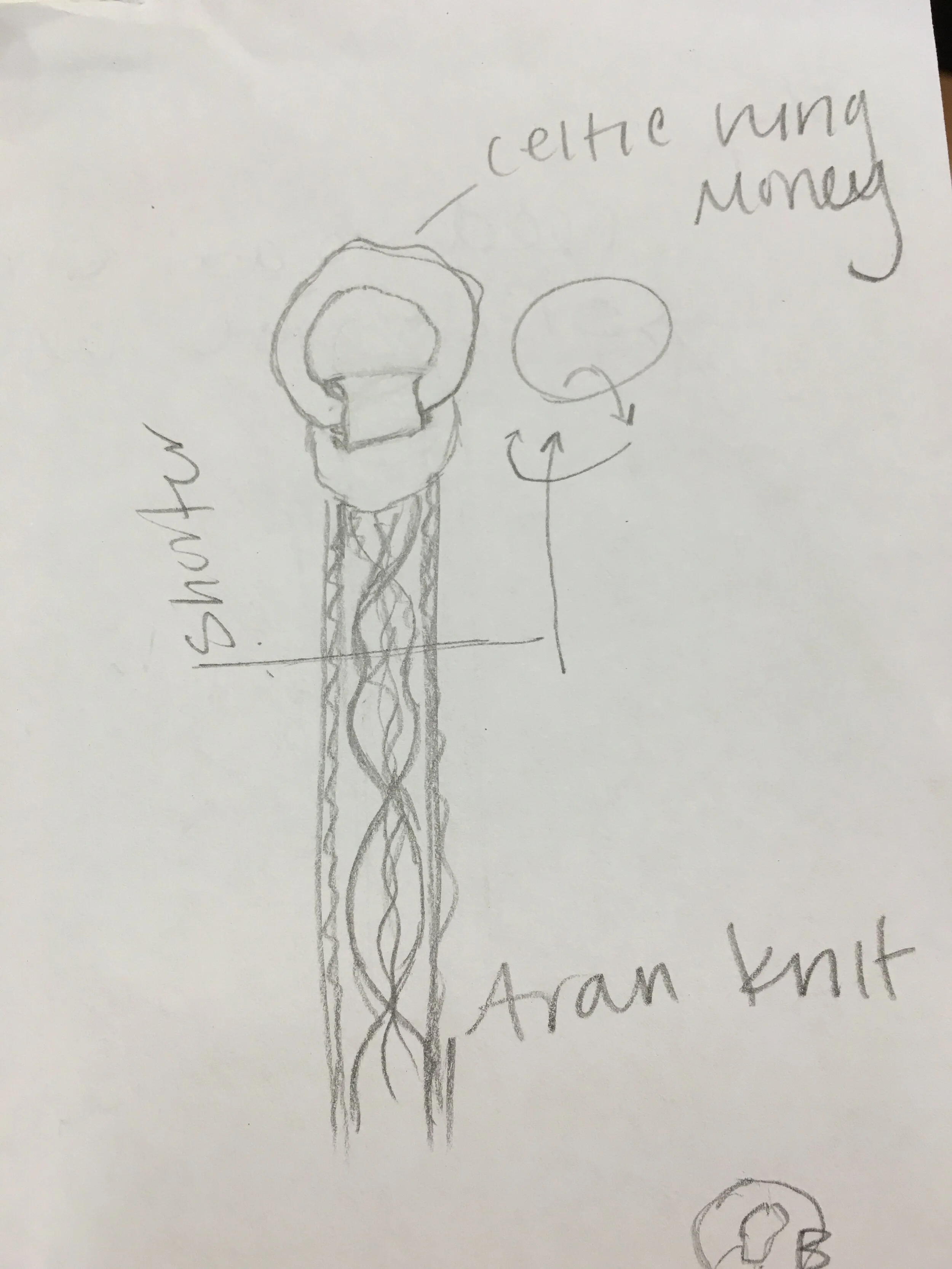

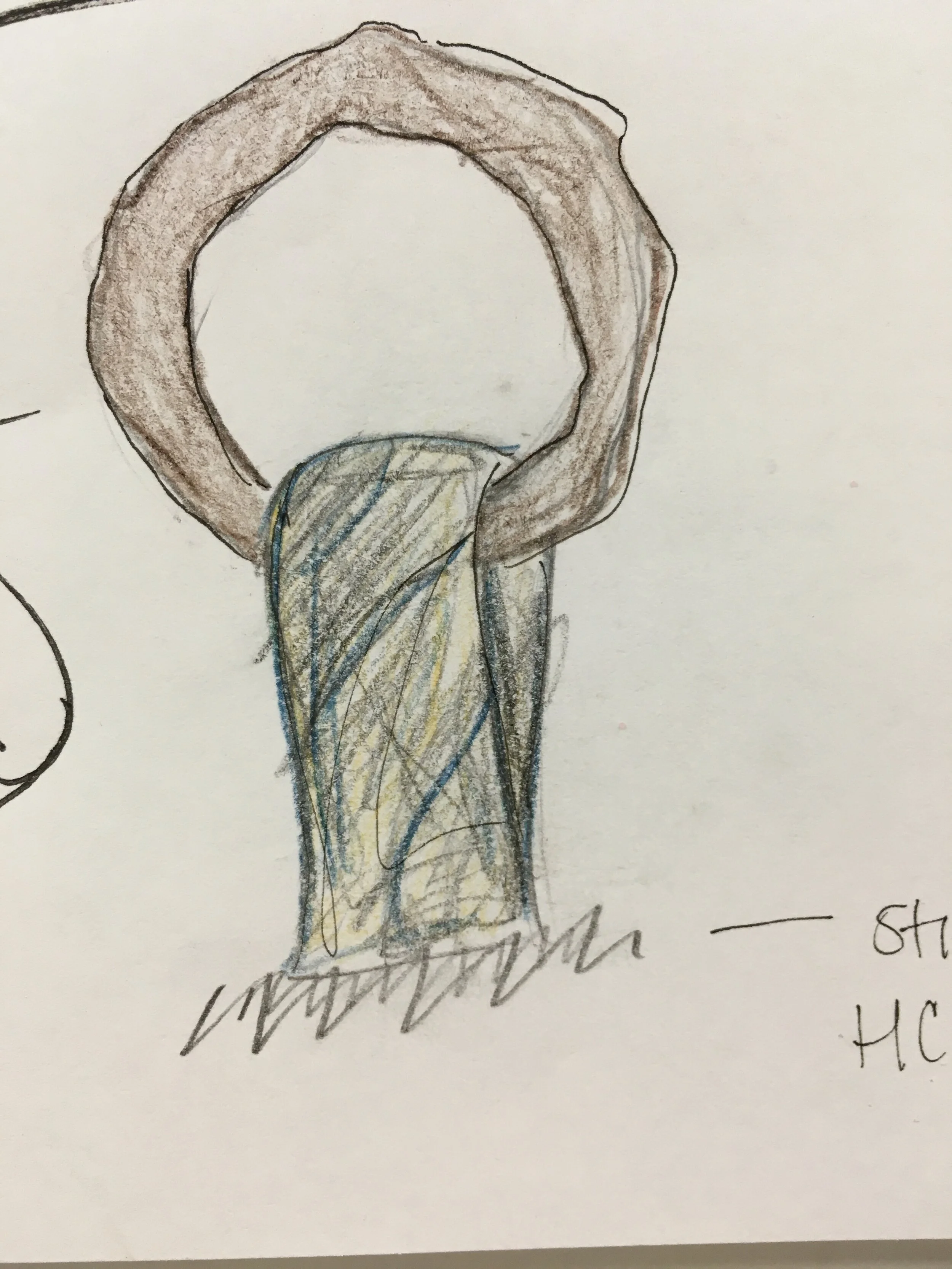

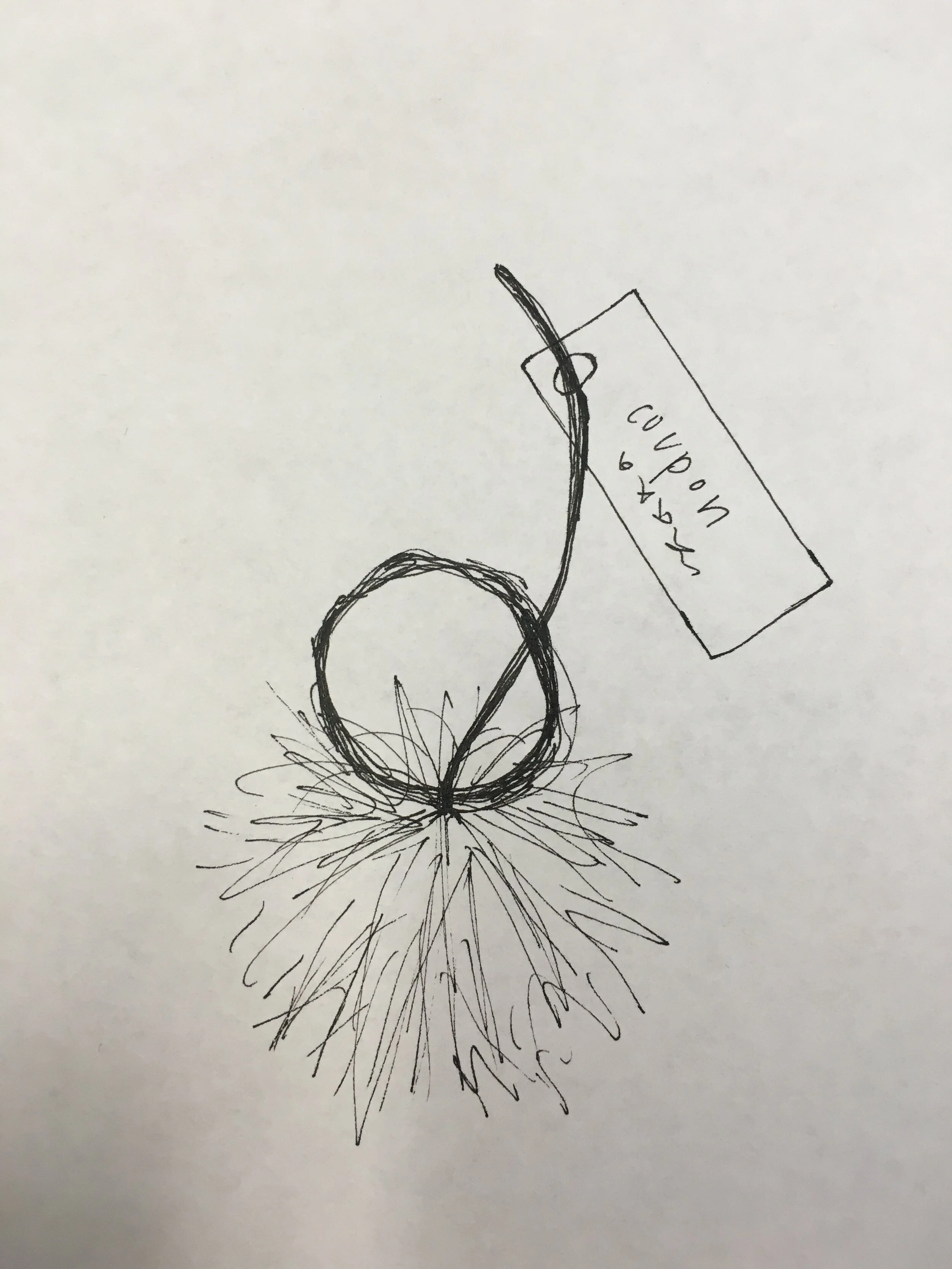

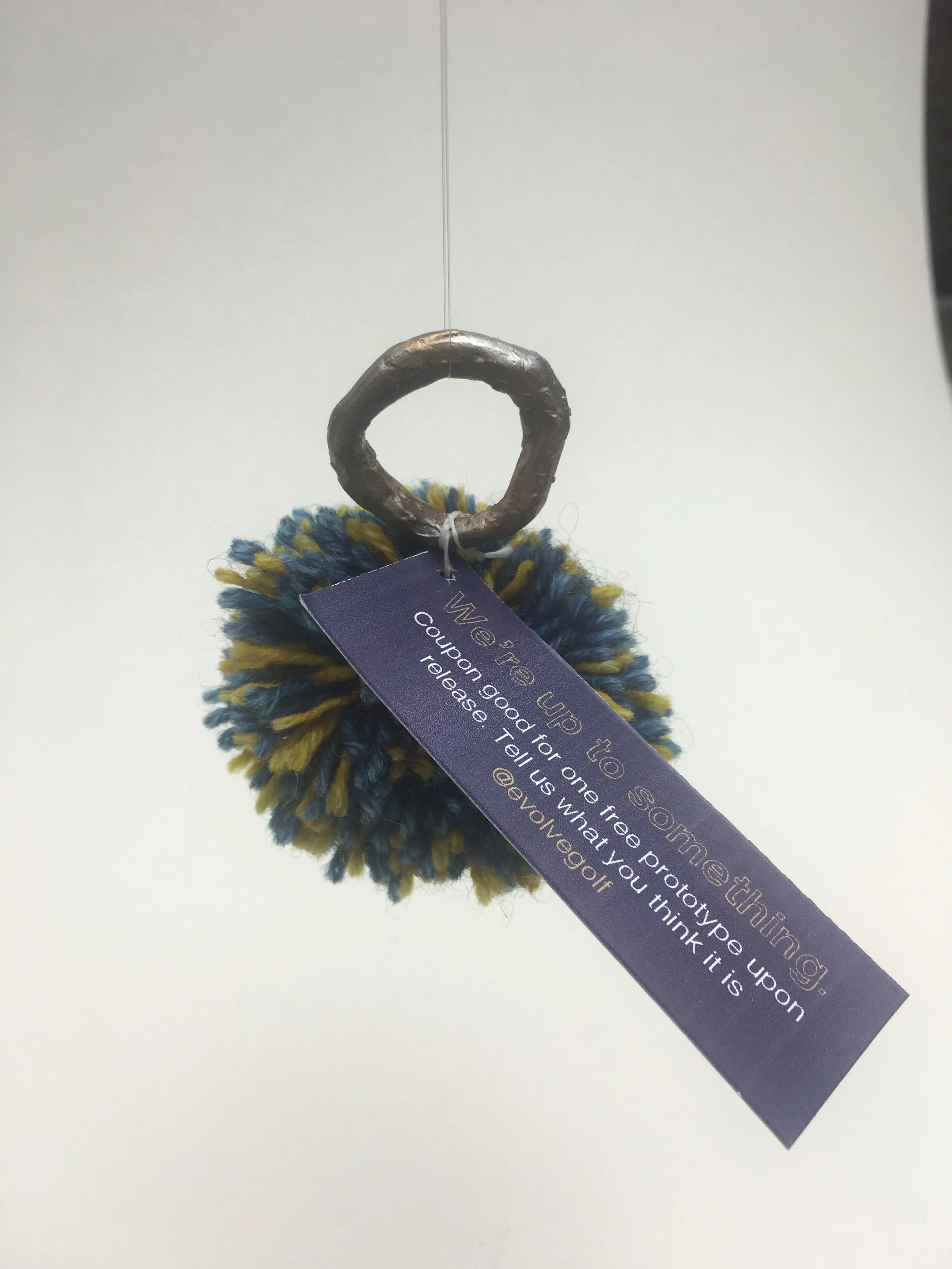

Bronze Headcover Ring-Pulls

designed + fabricated custom bronze rings, used as golf head cover pulls

equipment + processes: lost wax centrifugal casting, metal finishing with dremel tool

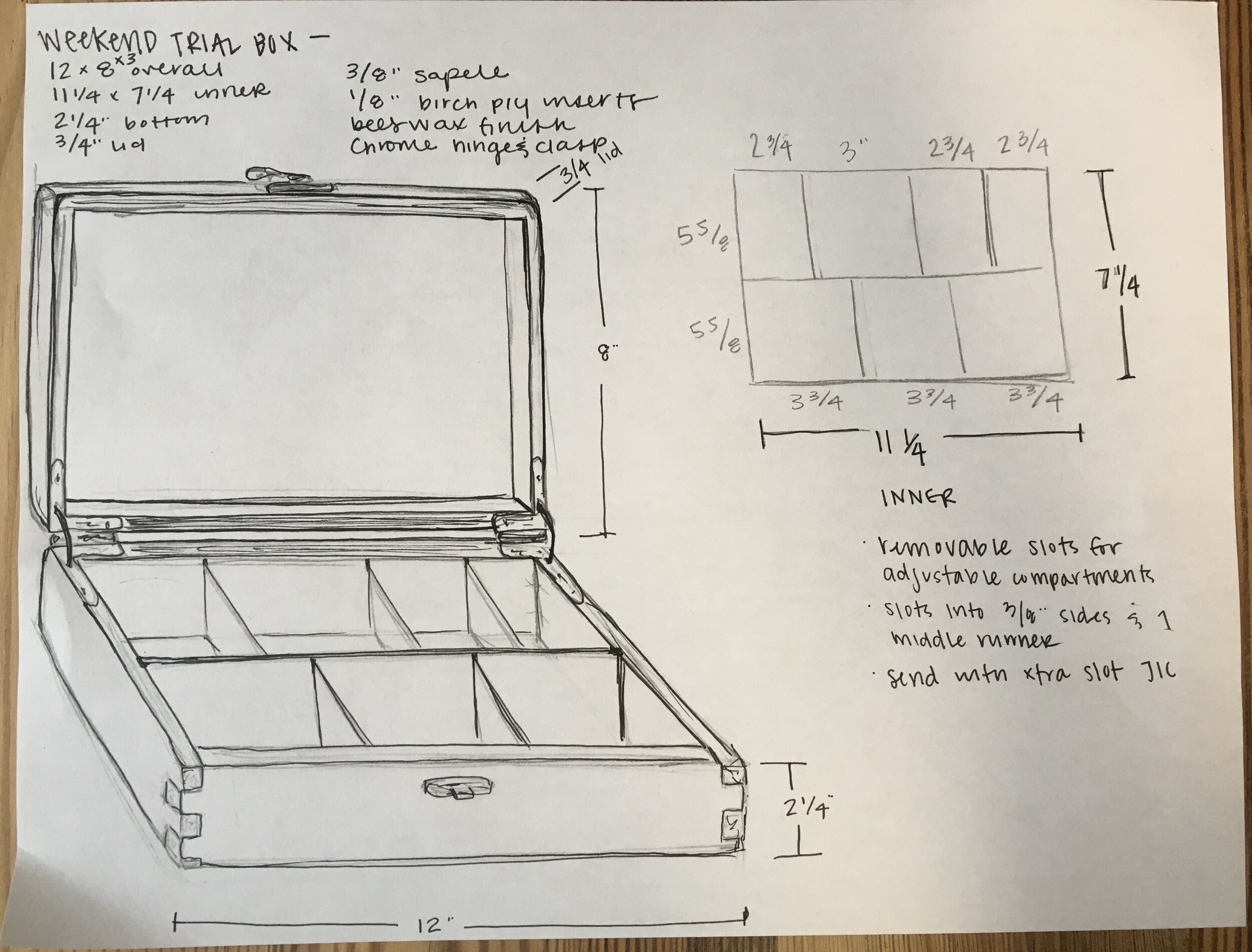

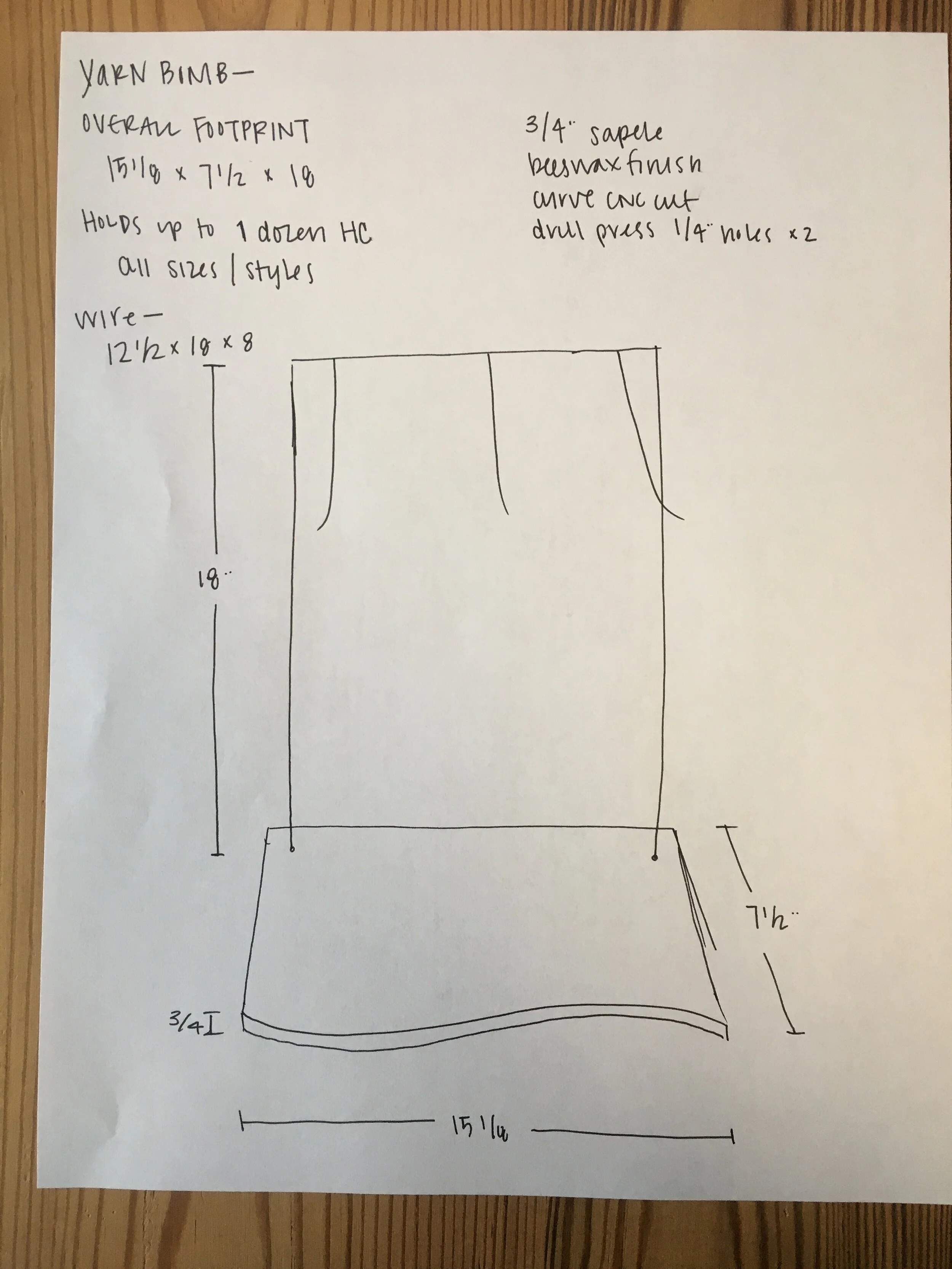

Weekend Trial Box

designed + built custom hinged and locking wooden boxes with removable inserts for branded golf accessories to be placed in private golf club pro shops

programs + equipment + processes: rhinoceros 3D, table saw, drill press, router